The construction industry needs reliable, innovative products to successfully maintain fire safety in buildings, whether for traditional building or offsite construction. Flame retardant panels improve a building's 'reaction to fire' as it has a much lower burn temperature after ignition, and a slower char rate, compared to an untreated wood-based panel. SMARTPLY MAX FR B, the first Euroclass B OSB/3 panel manufactured in the UK and Ireland to feature pre-treated wood strands, is a market innovation that brings increased safety and reliability to an industry contingent on predictability.

Benefits of flame retardant panels

The demand to build more homes in the UK shows no signs of slowing down, neither is the demand for innovations that can help the construction industry build better, safer houses – especially ones that can provide improved fire safety. Building materials such as flame retardant panels can help enhance fire safety in a property, be it residential or commercial.

What is flame retardance?

Flame retardant treatments are used to improve a material's 'reaction to fire,' which is the measurement of how a material or system will contribute to a fire's development and spread, particularly in the very early stages of a fire when evacuation is crucial.

A flame retardant panel has a much lower burn temperature after ignition, and crucially a slower char rate, compared to an untreated wood-based panel. This means the panel burns far more predictably and allows occupants more time to leave the building.

Building

with SMARTPLY MAX FR B

Building

with SMARTPLY MAX FR B

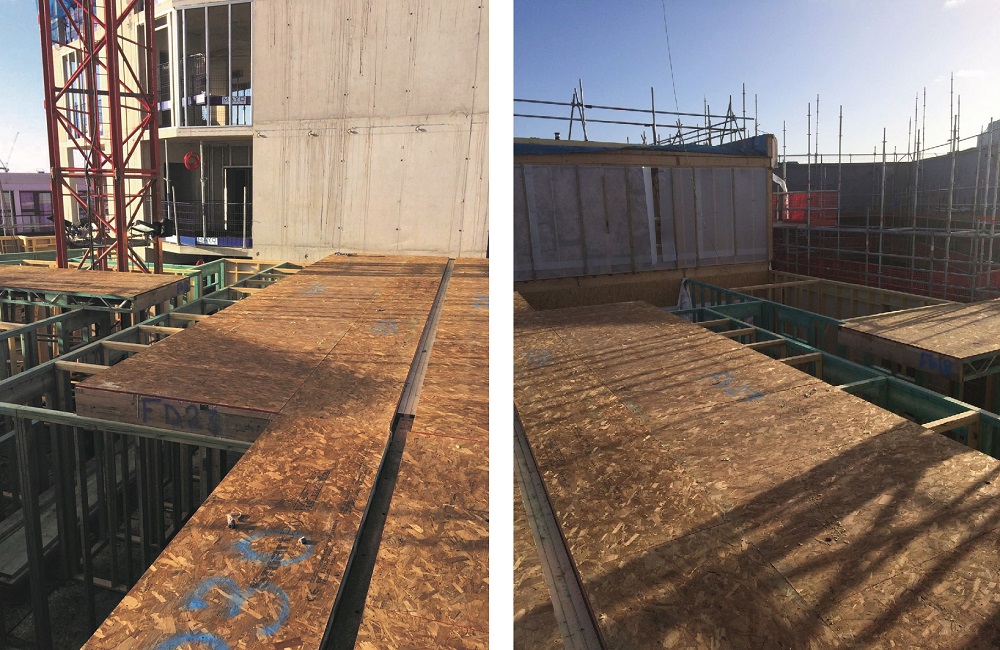

SMARTPLY MAX FR B is a flame retardant, structural, moisture resistant OSB/3 panel with outstanding and reliable reaction to fire properties. This robust panel is ideal for use where strength, moisture and improved flame retardance are paramount.

It is the first Euroclass B wood panel to be manufactured in the UK and Ireland to be treated with a water-based flame retardant solution during manufacture, allowing the individual wood strands making up the panel to be treated before pressing. Each panel is CE marked in accordance with EN 13986 at the point of manufacture unlike post-treated alternatives.

It achieves a Reaction to Fire Classification of B-s2, d0, and Bfl-s1 (flooring) in accordance with EN13501-1, which is the maximum rating for reaction to fire that a wood-based panel can achieve.

SMARTPLY MAX FR B panels are lightweight and easy to cut and fix compared to mineral-based panels, which can crack or shatter, giving fabricators and more flexibility to work with. It also complies with the performance requirements in the Structural Timber Associations "Design guide to separating distances during construction" for timber frame buildings. In this instance, the product is referred to as SMARTPLY MAX FR/FR BUILD.

An additional benefit of SMARTPLY MAX FR B is that it is available in largescale formats of up to 2.8m wide by 7.5m long – this makes it ideal for offsite manufacturing, as well as traditional building.

It is also sustainably manufactured using advanced resin technology that results in a higher performance, with no added formaldehyde. This makes it safer for contractors and fabricators to work with and helps create safer and healthier environments.

Find out more about SMARTPLY MAX FR B and see what it can do for your project: https://mdfosb.com/en/products/smartply-max-fr-b