According to surveys, 96% of supply chain firms are affected by labour shortages. As the UK construction industry continues to feel pressure to ensure on-time and on-budget delivery, innovative use of new technology and digital software supports a whole new skill set. Mark Munns, CEO of Frameclad, considers how light steel systems can benefit contractors struggling with the labour gap.

Production of light steel framing solutions has shifted considerably in the last decade. Manufacturing now requires far less labour and relies more on automated processes managed by skilled operatives. This can be of significant advantage to developers.

The fact that we can provide faster, simpler installation with the requirement for less skilled workers on site has benefits not only in terms of cost but in improved productivity and safety. We are offering something precision engineered and turning to technology allows us to offer something highly specialised and project-specific. What might have taken an entire team several weeks if not years to complete is now quicker, safer and more cost-effective.

We can offer more comprehensive light steel framing systems through experienced engineers working alongside digital experts to improve design and integrate new technology into our production processes. We need to think of our workforce in the same way as we do the systems we offer – the sum of many parts, working with synergy. I think as a sector, light steel is leading the way in that aspect.

For more information on light steel framing systems and services visit: www.frameclad.com

IMAGE

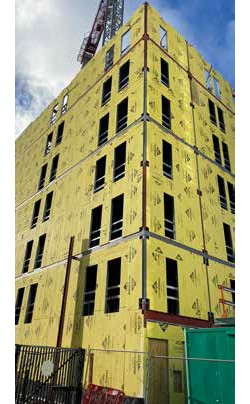

01. Frameclad's Concord Street project